Product description:

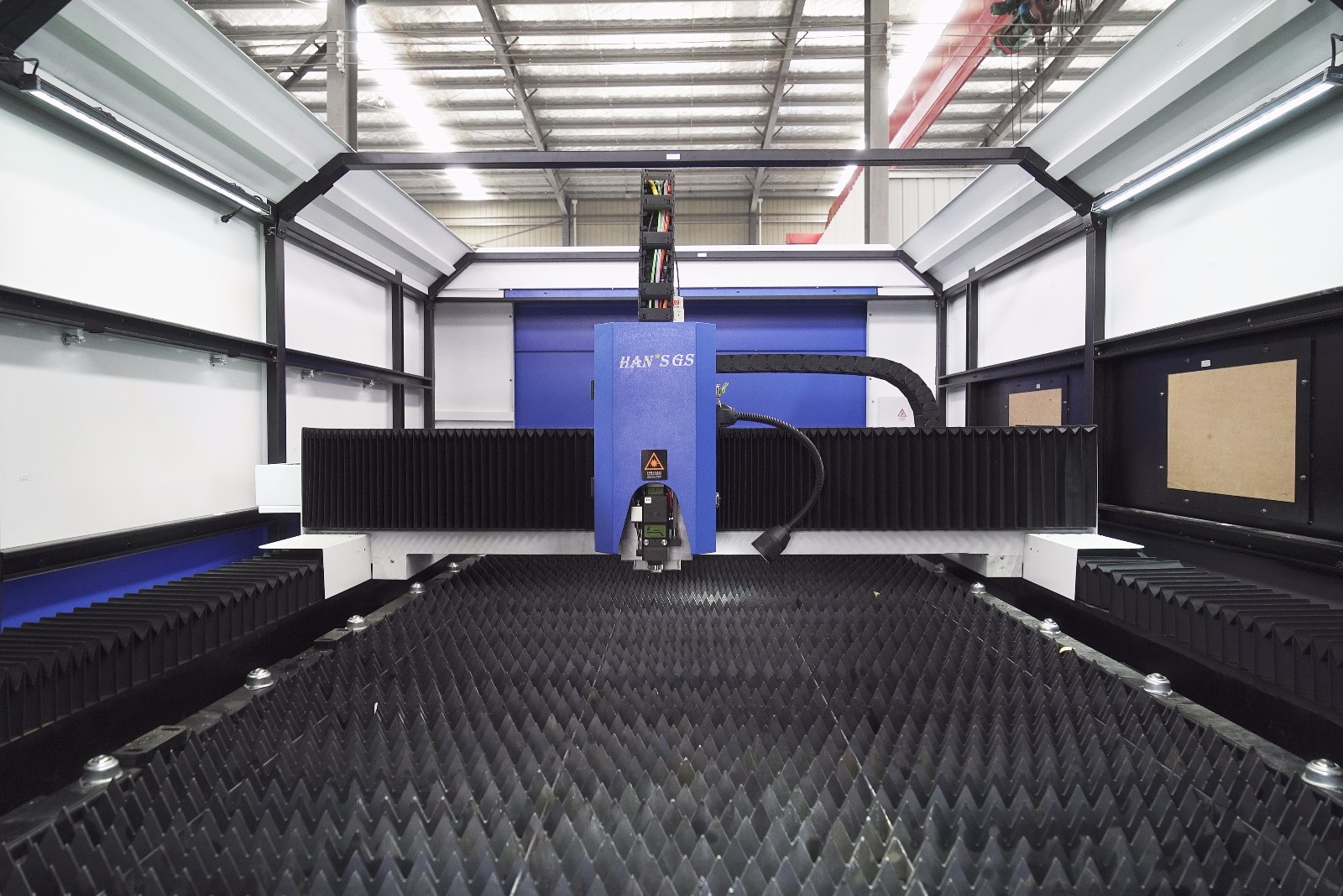

CNC Laser Cutting Machine Features:

1.Double drive system,YASKAWA,helical gear drive.Drive faster,more stable

2.12mm Steel frame,more firmly

3.Gantry beam,cast aluminum.High performance,no deformation,light weight and working fast

4.Control cabinet air condition,more secure,more intimate

5.Removable control cabinet,maintenance more convenient

6.Famous system, Beckhoff CNC Control System

7.Safety protection of cutting head,focal length adjustment,drawer type protective lens

8.Cooling system,water cooling and air cooling

9.Lubrication system,manual one key lubrication and computer control automatic lubrication

10.Material protection feeding system,three sides pulley feeding and hydraulic pressure push rod feeding

11.Double dedusting system,more environmentally friendly and safe.

Specifications

Model | GS-LFDS3015 | GS-LFDS4020 | GS-LFDS6020 |

Laser source medium | Fiber |

Cutting range(L*W) | 3000mm × 1500mm | 4000mm × 2000mm | 6000mm × 2000mm |

Z axle stroke | 250 mm |

Max positioning speed | 120m/min |

X、X,Y axle Max accelerate speed | 1.2G |

Cooling form | water cooling |

Laser wavelength | 1070nm |

Output power of laser source | 1000W~ 4000W(imported) |

Min. cutting gap | ≤0.1mm |

Positioning accuracy of X, Y and Z axles | ±0.03 mm |

Repeated positioning accuracy of X, Y and Z axles | ±0.01mm |

Thickness of cutting material (according to material) | 0.2-25mm |

Drive model | Imported servo motor |

Power requirement | 380V,50/60Hz |

Working temperature | 5℃-45℃ |

Continuous working time | 24 Hours |

Machine weight | About 11440Kgs |

Outer dimension | 8500mm x 3800mm x 2000mm |

Total protection level of power supply | IP54 |

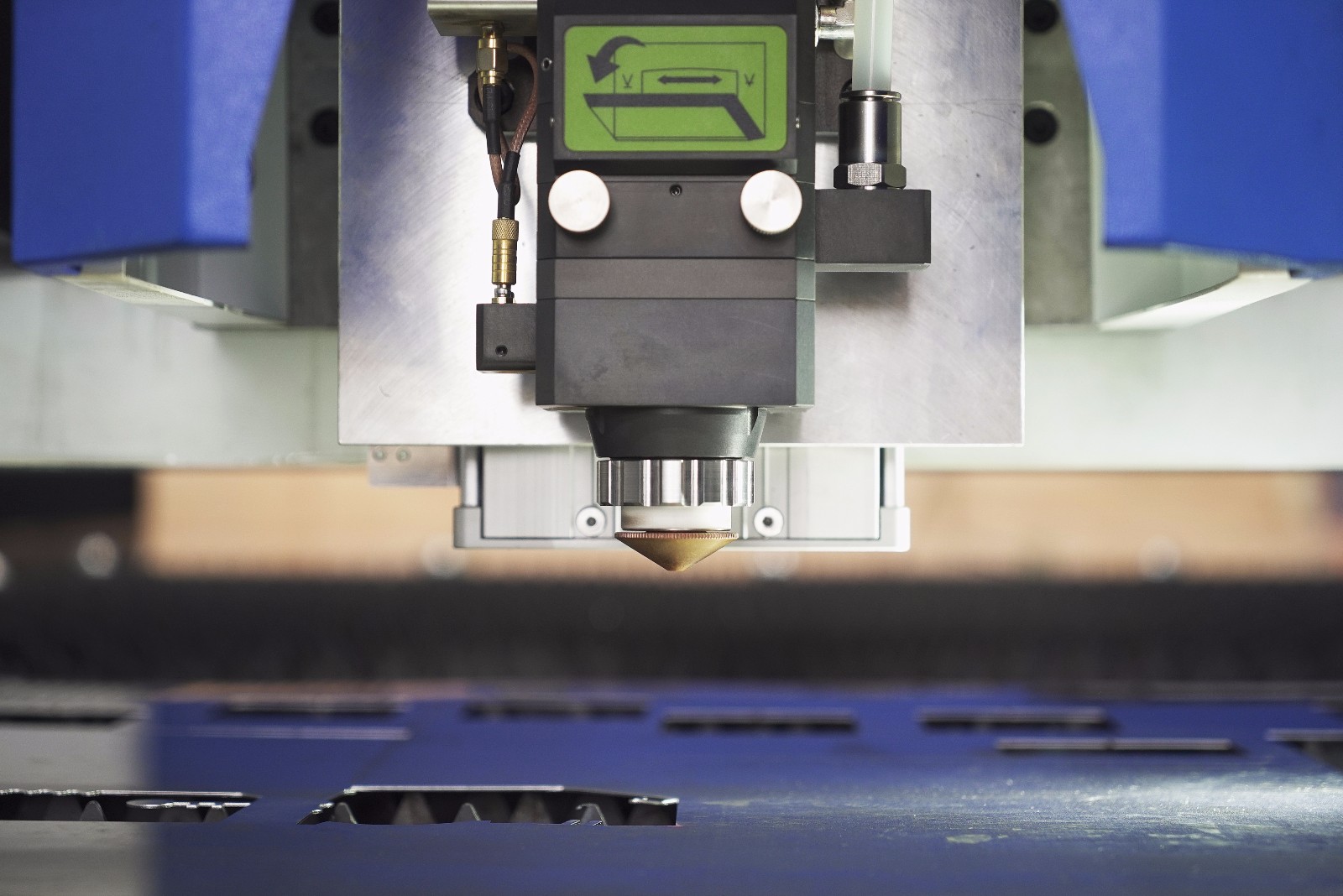

Switzerland Original Raytools Laser Cutting Head

Laser cutting head of stable performance and convenient operation and maintenance

1. non contact capacitor auto tracking system , Z-axis floats stability, auto adjusts optimal focal distance.

2. Two different focus lenses, adapt to cutting various thickness materials, assure the optimal cutting effect.

3. The

laser cutting head can bear 2.0Mpa pressure, high pressure gas path,

improve cutting ability for the materials difficult to cut such as

stainless steel.

Servo Motor of strong rigidity, excellent control ability, accurate, sensitive response

1. Outstanding performance with the highest level of response of amplifier in the industry, the setting time is shortened in a high degre

2. Enhancement of the Vibration suppression function to improve the track ability and decrease the setting time. Reduce the vibration when driving and reduce the fore-end vibration when stop working

3. Easy start up: simple installation and setting. The connection can be finished one time with Sigma Win+Connection confirmation function.

4. Standard configuration with analog quantity, instruction form of pulse sequence type and MECHATROLINK-II communication command type.

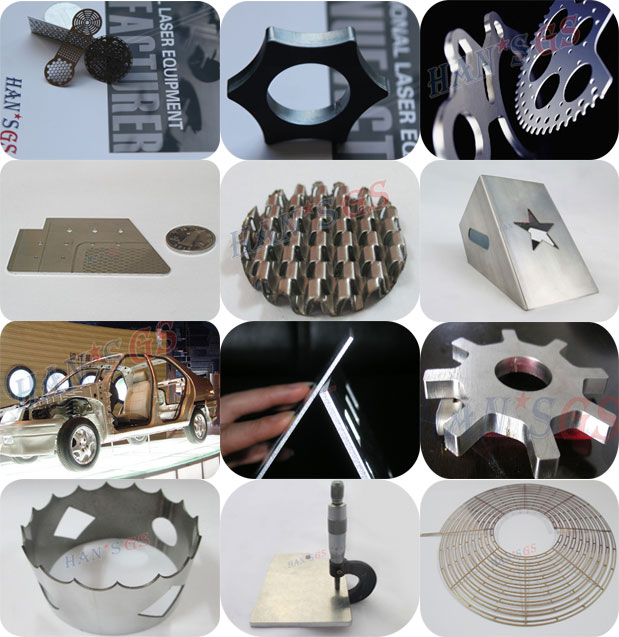

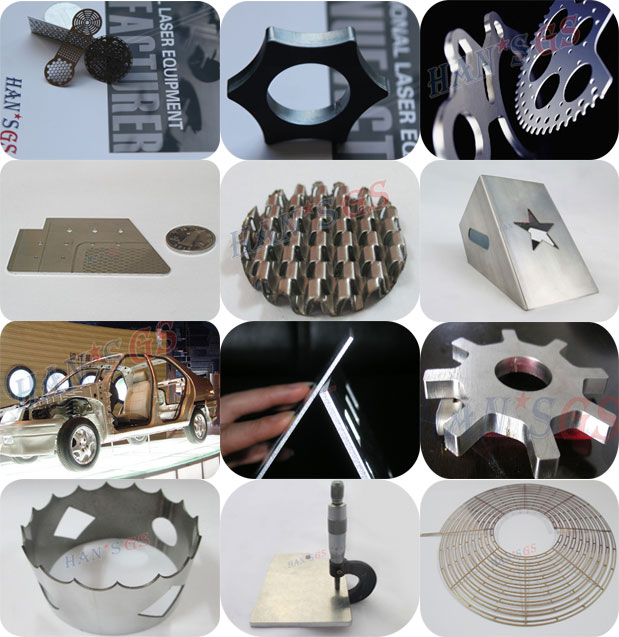

Cutting Materials

It is used to cut the metal materials,such as stainless steel, carbon steel, alloy steel, silicon steel, spring steel, galvanize plate, pickled plate, copper plate, aluminum plate, etc.

Application Industry

Widely used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, tube fittings, automobile, food machinery, engineering machinery, precision parts, ships, metallurgical equipment, elevators, household appliances, kitchen utensils and appliances, craft gifts, tool processing, decoration, advertising and other manufacturing industries.

HANS GS FAQ:

1.Q: Are you a factory or trading company?

A:We are a manufacturer with $13 million registered capital & 20000 square meters Han’s Goldensky Science and technology park.

2.Q: What is the payment terms?

A:The payment terms we accept include: Western Union, Cash, L/C, T/T (30% advance payment as deposit, 70% balance payment should be paid before shipment.)

3.Q: How long is the delivery date?(After getting the deposit)

A: It is different from 25-45 workdays according to the models, OEM is also available, delivery time need to be final confirmed on both sides.

Cutting Sample

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam