HANS GS Robot 3D Laser Cutting Machine is mainly composed of fiber laser cutting head, high-precision capacitive tracking system, fiber laser source and industrial robot system.Features are highly flexible, you can cut different thickness of the metal sheet, multi-angle, multi-directional flexible cutting.At present, HANS GS Robot 3D Laser Cutting Machine equipment is widely used in sheet metal processing, metal processing, advertising production, kitchen utensils, automobiles, lamps, saw blades, lift elevators, metal crafts, textile machinery, food machinery, Medical equipment, instrumentation and other industries.Especially in the sheet metal processing industry has replaced the traditional processing methods, favored by industry users.

HANS GS Robot 3D Laser Cutting Machine processing of different materials, stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, Aluminum Alloy, galvanized plate, aluminum zinc plate, pickling plate, copper, silver, gold, titanium and other metal plate and pipe.

HANS GS Robot 3D Laser Cutting Machine Typical applications

1, Processing high-strength steel

Trimming is another challenge for high strength steels. Three-dimensional laser cutting machine for forming sheet metal trimming, especially for the strength of up to 1500MPa of steel, because no other processing methods can be replaced. Because in the processing of these high hardness of the material, the traditional equipment die or tool life will be greatly reduced, and laser cutting do not have to consider these issues, but also has a short installation time, flexible replacement of products or sample production and other advantages.

2 , Cutting the side of the car

The side wall is made of high strength steel by hot forming. It has high hardness and bears great stress. The B side of the high strength steel increases the impact resistance and improves the safety of the automobile. It is also the reason why carmakers are willing to use them despite the high cost of high-strength steel.For laser bumper hole equipment, automobile bumper is shaped by stamping, the traditional way is very complex, and the parts prone to deformation and stress by using the laser cutting method, does not require complicated machining fixture system, no stress, no deformation, no burr cutting El, edge collapse, more suitable for post processing and installation.

In the field of automobile manufacturing, the use of laser technology, the automobile manufacturing processing of high precision, good quality, easy automation, flexible and intelligent; more important is to improve the safety quality of automobile, clean production and reduce the loss and pollution, reduce the costs and finally offers to ordinary consumers, science and technology the beauty of life achievements, achievements of automotive beauty laser.

Characteristics of HANS GS Robot 3D Laser Cutting Machine

1, high flexibility, especially suitable for small size three-dimensional sheet metal cutting.the adaptability of the material, through numerical control procedures can basically cut any plate.the processing path is controlled by the program, if the processing object changes, only the modified procedures, this point in trimming, cutting holes is evident, because the trimming die and the punching die for different parts of the processing and the high cost of mold incapable of action, so that the 3D laser cutting to replace and repair the side mold and punching die trend. Generally speaking, the design and use of fixture in 3D machining are more complicated, but the machining force is not exerted on the machined plate during laser processing, which makes the manufacture of jigs very simple. In addition, if a laser device is equipped with different hardware and software, it can realize many functions.

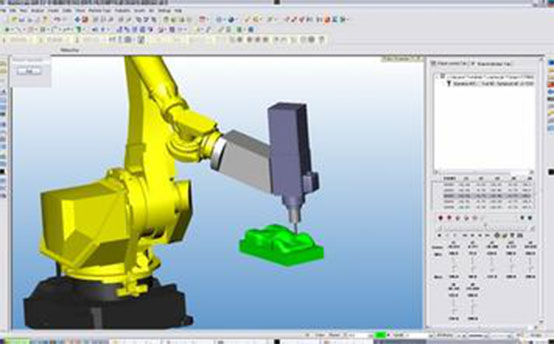

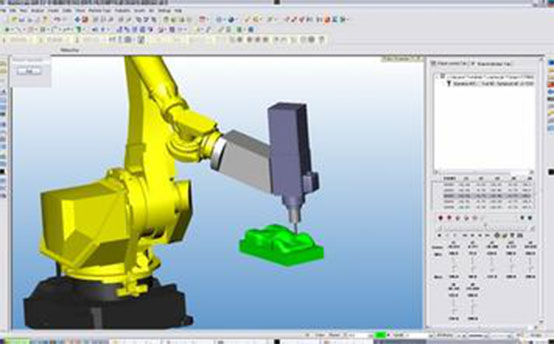

2, The combination of industrial robot + fiber laser processing, trimming and punching process once completed, neat incision without re treatment after the process, greatly shorten the process, reduce the labor cost and tooling cost investment, improve product quality and added value. Selection of off-line programming software, through direct numerical simulation of generating cutting trajectory, abandoned the complicated manual teaching, cutting more suitable for small batch and multi batch maintenance market, new products and non-standard customized and personalized.

Advanced fiber laser technology and digital control technology perfect fusion, represents the most advanced laser cutting machine; control system, professional computer laser cutting operation, to ensure the quality of cutting, the cutting work more convenient, more simple operation; configuration of intelligent manipulator, which can realize three-dimensional cutting, easy control, intelligent degree to ensure the high, high speed, high precision and high reliability of equipment; laser cutting head configuration of imported laser cutting head, sensitive and accurate, effective coordination with the manipulator, cutting head and processing plate collision avoidance, and can guarantee the cutting focus position, ensure the quality of cutting stability; laser cutting head can withstand 1.0MPa gas pressure, high pressure pneumatic equipment, improve the cutting ability of stainless steel and other hard cutting materials.

In a word, in the actual production, HANS GS Robot 3D Laser Cutting Machine has obvious advantages in improving product quality, production efficiency, shortening product development cycle, reducing labor intensity and saving raw materials. Therefore, despite the high cost of equipment, one-time investment, there are still a lot of domestic cars, aircraft manufacturers purchase 3D laser processing machine, some colleges and universities have also purchased the corresponding equipment for scientific research, 3D laser technology is in our country manufacturing industry is playing an increasingly important role.

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam